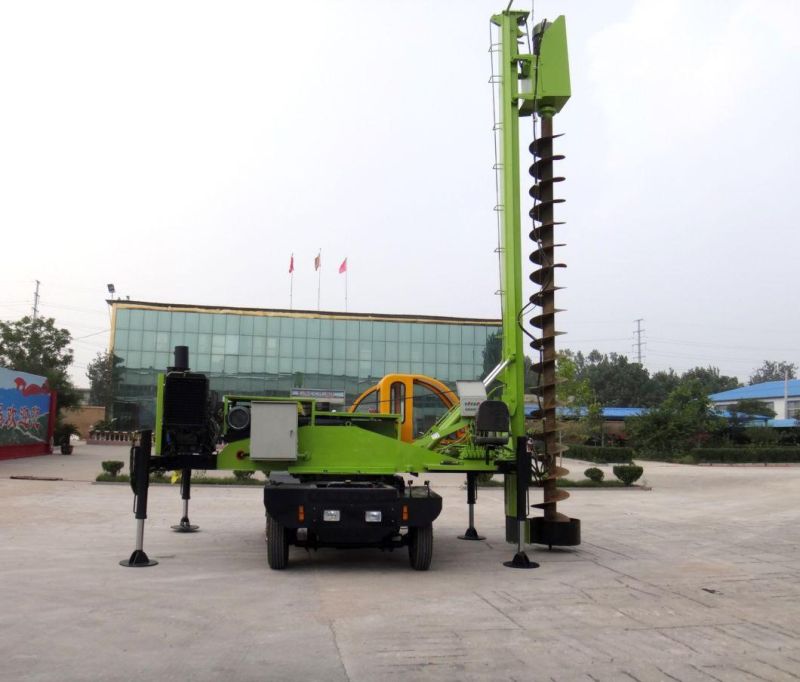

Wheeled 360-6 Screw Pile Driver for Construction of Bridges and Water Conservancy Projects

SHANDONG HIGHWAY MACHINE CO., LTD.- Certification:CE, ISO 9001:2000, ISO 9001:2008

- Condition:New

- Drill Hole Diameter:100-800mm

- Drill Hole Depth:6-11m

- Bit Type:Core Bit

- Drilling Way:Rotary

Base Info

- Model NO.:Wheeled 360-6

- Type:Four-Wheel Trailer

- Weight:6500kg

- Engine Power:34kw

- Engine Rotation Rate:2200r,Min

- Generating Set Power:40-50kw

- Transport Package:Export Standard Packing

- Specification:7300*2100*2850mm

- Trademark:LIQIANG, HAIWEI

- Origin:China

- HS Code:8430412200

- Production Capacity:800sets,Year

Description

1.The upper frame and the lower frame can rotated 360°, and the upper frame can be slided 80cm forward and backward, also can be worked in all directions.2.With fast piling speed, one 6m depth can be finished in 3 minutes.

3.remote control is available and much more simple.

4.two walking pattern are supported: hydraulic walking and electric walking (with generator set)

5.accessories and electrical appliances are the products of well-known manufacturer with high quality assurance.

FAQ

Q1: What is the Warranty of the Rotary Drilling Rig?

The warranty period for new machine is half a year or 1000 working hours, whichever comes first will be applied.

Please contact with us for detailed Warranty Regulation.

Q2: What's your service ?

We can offer professional technical support and good after-sale service to you.

Modification methods will be different according to different models and configurations of your owned machine.

Before modifying, you need to provide configuration, mechanical and hydraulic joints and others.

Before modifying, you need to confirm technical specification.