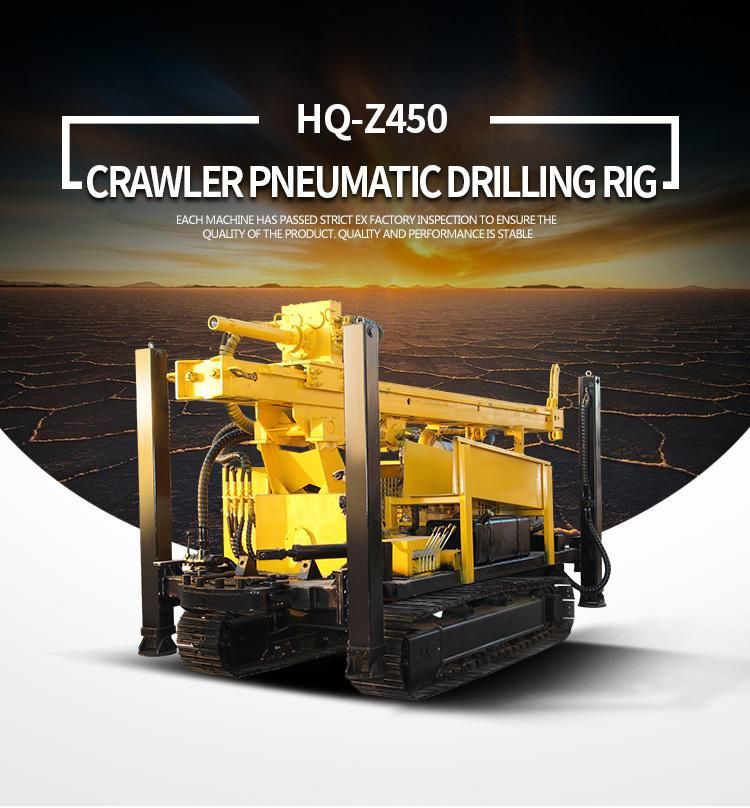

Crawler Air Type Hydraulic Water Well Drilling Machine Deep Wells Drilling Rig

Ji Ning Hengwang Mining Machinery Co., Ltd.- Certification:CE, ISO 9001:2008

- Condition:New

- Motor:DC Motor

- Drill Hole Diameter:250-300mm

- Drill Hole Depth:450m

- Bit Type:Diamond Bit

Base Info

- Drilling Way:Impactor

- Type:Water Well Drill Rig

- Model:Hw200

- Max. Drilling Diameter:70-300mm

- Max. Drilling Depth:450 M

- Total Power:7.5 Kw

- Usage:Water Well

- Power Type:Air Compressor

- Transport Package:Wooden Case

- Specification:CE

- Trademark:HW

- Origin:Shangdong China

- HS Code:84304122

- Production Capacity:50000set,Year

Description

Basic Info.

Drilling Way Impactor Type Water Well Drill Rig Model Hw200 Max. Drilling Diameter 70-300mm Max. Drilling Depth 450 M Total Power 7.5 Kw Usage Water Well Power Type Air Compressor Transport Package Wooden Case Specification CE Trademark HW Origin Shangdong China HS Code 84304122 Production Capacity 50000set/YearProduct Description

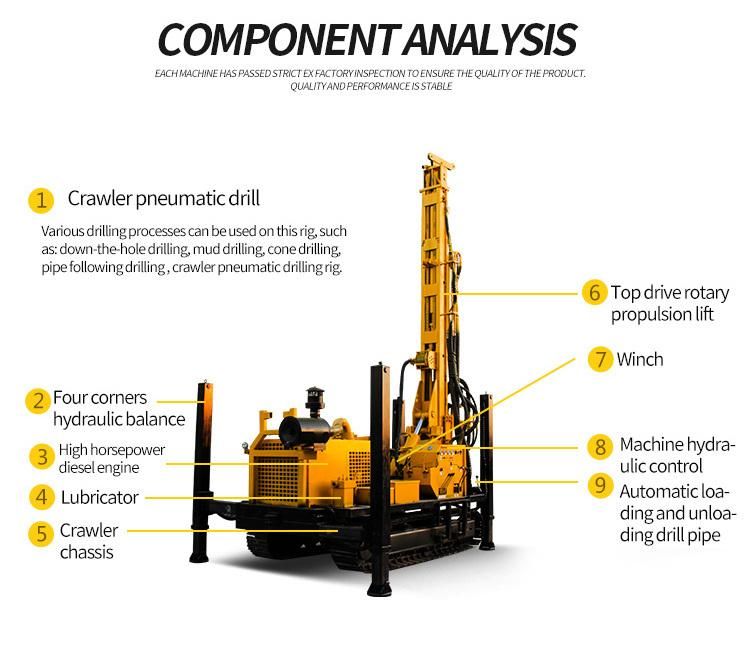

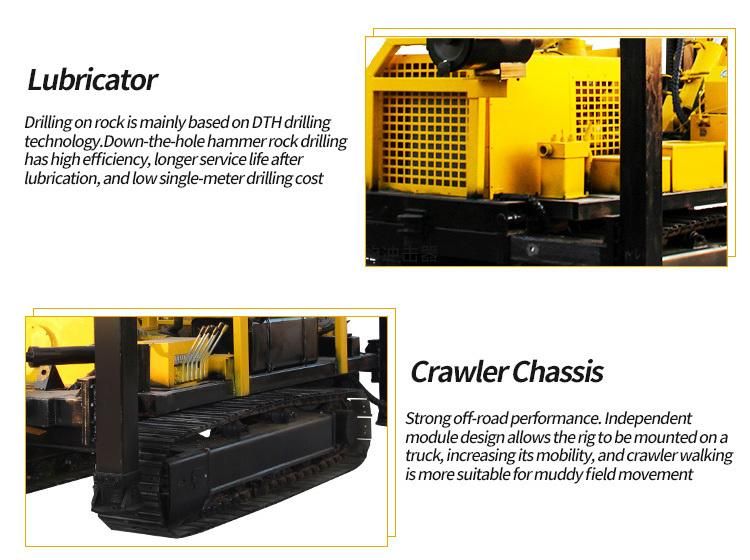

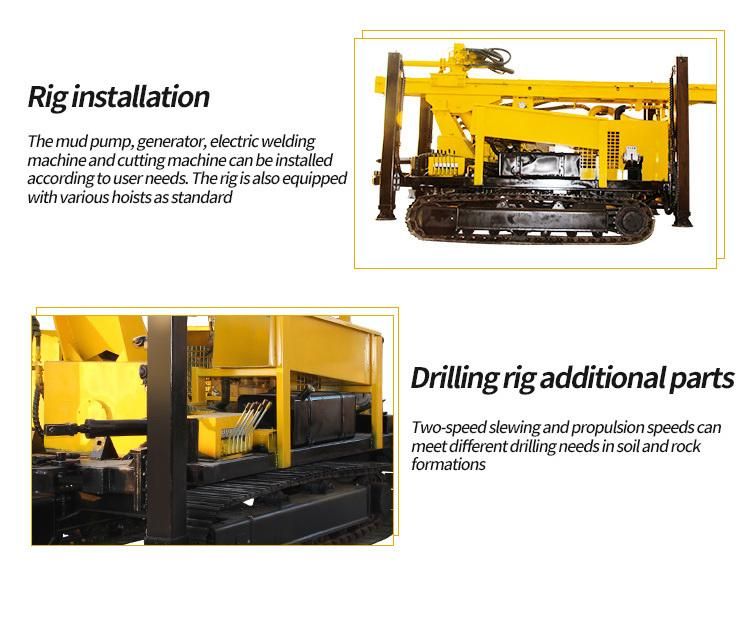

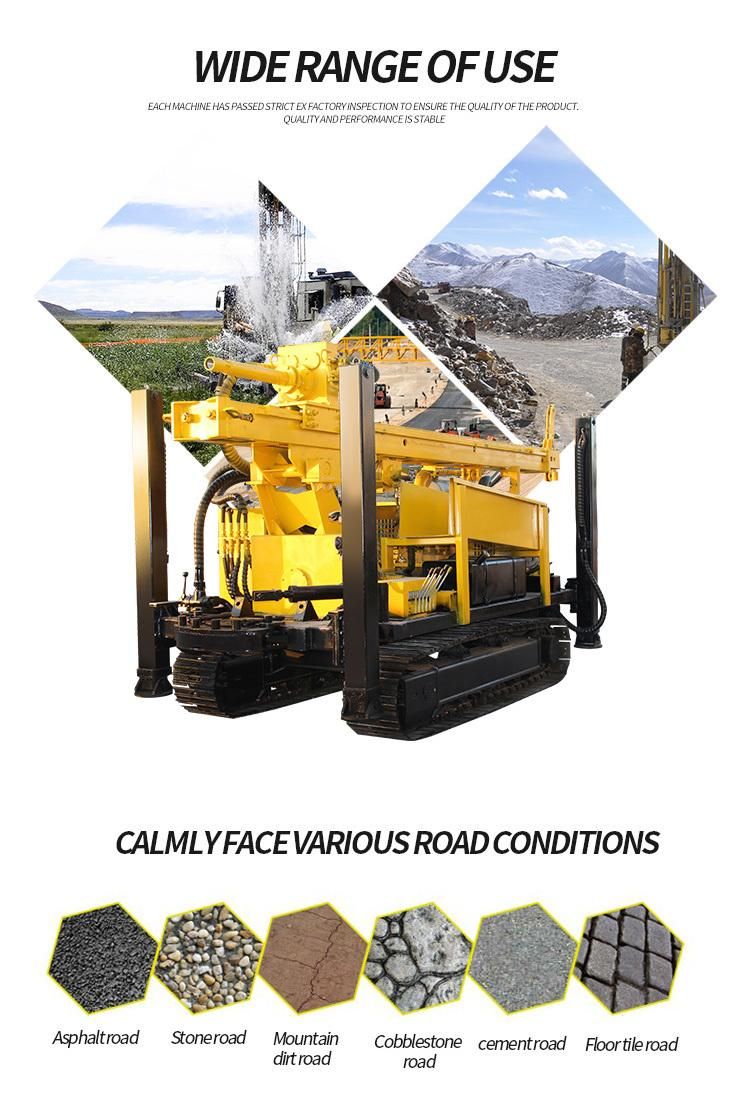

crawler borehole drilling rig are multifunctional, it can be used with air compressor, mud pump, even we can just use the dry hydraulic drilling method.

The drilling rigs are not only designed for water drilling. deep water well drilling rigs can be used in all conditions based on pore-forming purpose.

They are widely used in industrial and agriculture water project, testing well and other exploration borehole. In particular, drilling hole for geothermal heating, it can also meet the engineering basis for reinforcement, loose gravel drilling rock formation connected with a variety of engineering.

450M crawler borehole drilling rig

| Weight | 12T |

| Dimensions | 6000*2200*2850MM |

| Drilling diameter | 140-350MM |

| Drilling depth | 450M |

| One advance length | 6600MM |

| Walking speed | 2.5KM/H |

| Standby climbing ability (max) | 30 |

| Minimum ground clearance | 250MM |

| Working pressure | 1.7-3.5MPA |

| Air consumption | 17-35M3/MIN |

| Host power | 110KW |

| Rotation speed | 45-115KW |

| Rotary torque | 8500-11000NM |

Our crawler borehole water well drilling rigs are more efficiency and with low failure rate, more economic and durable, and with a high comprehensive cost performance.