Mine Drilling Rig Zdy-4000s Hydraulic Coal Mine Tunnel Well Rock Rotary Drilling Machine/Rigs Get Latest Price

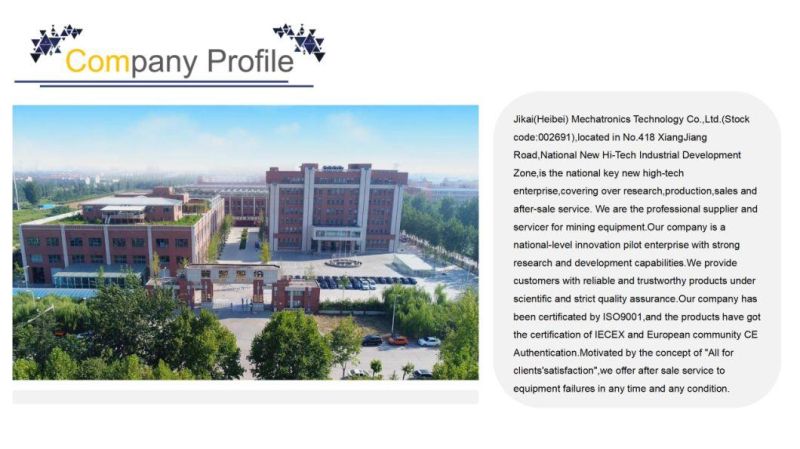

Jikai(Hebei)Mechatronics Technology Co., Ltd.- After-sales Service:Service Machinery Overseas

- Warranty:12 Months

- Certification:CE, ISO 9001:2000, Atex

- Condition:New

- Motor:AC Motor

- Drill Hole Depth:<100m

Base Info

- Model NO.:Zdy-4000s

- Bit Type:Diamond Bit

- Drilling Way:Rotary

- Transport Package:International Carton

- Specification:1800*620*1300

- Trademark:JIKAI

- Origin:Shijiazhuang City Hebei Province China

- Production Capacity:1000pieces ,Year

Description

Basic Info.

Model NO. Zdy-4000s Bit Type Diamond Bit Drilling Way Rotary Transport Package International Carton Specification 1800*620*1300 Trademark JIKAI Origin Shijiazhuang City Hebei Province China Production Capacity 1000pieces /YearProduct Description

JIKAI Technology Company is ProfessionalManufacturer of Underground Mining Equipment

ZDY coal mine drill rig mainly used for large diameter roller boring and core drill bits, PDC drill bits drilling. It is widely used in coal mine, non ferrous metal, hydropower construction, public works, nuclear industry, geological industry, military construction for drilling holes for water exploring and injection, gas exploring and discharging, geological exploring, bolting on slope and other drilling works. It is special suitable for horizontal drilling hole and can be adjusted within ±90°to drill holes in the tunnel.

The drill rig adopts entire hydraulic system. It consists of main frame, pump station and operational panel, which is easy to disassemble and transport. Under bad transportation condition, the main frame also can be disassembled. It is light weight, small size, easy operation, with good performance, simple structure and easy to maintain.

| Item | Main Parameters | ZDY-4000S |

| 1 | Drill Depth (m) | 400 |

| 2 | Boring Inclined Angle (º) | ±90 |

| 3 | Boring Diameter (mm) | Φ108-Φ200 |

| 4 | Rated Torque (N.m) | 4000-1050 |

| 5 | Rated Rotating Speed (r/min) | 60-230 |

| 6 | Feeding Stroke (mm) | 800 |

| 7 | Feeding Force (kN) | 150 |

| 8 | Pulling Out Force (kN) | 150 |

| 9 | Max. Feeding Speed (m/min) | 18 |

| 10 | Max. Pulling Out Speed (m/min) | 18 |

| 11 | System Rated Pressure (Mpa) | 25 |

| 12 | Oil Tank Capacity (L) | 250 |

| 13 | Main Frame External Size (mm) | 2300x1170x1600 |

| 14 | Pump Station External Size (mm) | 1890x810x1150 |

| 15 | Main Frame Weight (kg) | 1780 |

| 16 | Pump Station weight (kg) | 866 |

| 17 | Operation Desk Weight (kg) | 136 |

| 18 | Drill Rig Weight (kg) | 2800 |

| Anti-explosion electric motor | ZDY-4000S | |

| 19 | Rated Power (kW) | 55 |

| 20 | Rated Voltage (V) | 660/1140 standard (380/660 optional) |

| Fitted drilling tools | ZDY-4000S | |

| 21 | Geological Drill Rod Diameter (mm) | Φ73(1:4 conical buckle,standard) Φ63.5 (optional) |

| 22 | Geological Drill Bit Diameter (mm) | Φ90/Φ94/Φ108/Φ133 |

| 23 | Triangular Drill Rod Diameter(mm) | Φ73(1:4 conical buckle,standard) Φ63.5 (optional) |

| 24 | Wide Blade Spiral Drill Rod Diameter(mm) | Φ73(1:4 conical buckle,standard) Φ63.5 (optional) |

| 25 | High Strength High Efficiency Spiral Drill Pipe(mm) | Φ96 (optional) Φ98 (optional) |

At present, our company has built an advanced R&D system:Since 2007, the company has realized the network and digitization of R&D and design work;3D solid design and finite element analysis;Implemented product data lifecycle management (PLM);project workflow management; the integration of PLM system and ERP system;the paperless application of drawings and all technical data.

At present, our company has built an advanced R&D system:Since 2007, the company has realized the network and digitization of R&D and design work;3D solid design and finite element analysis;Implemented product data lifecycle management (PLM);project workflow management; the integration of PLM system and ERP system;the paperless application of drawings and all technical data.For example: 3D integral casting scraper conveyor not only greatly improves the service life of the scraper, but also promotes the intelligent construction of fully mechanized mining;Anti-gas and anti-groundpressure automatic drilling rig, equipped with remote control and video monitoring system, with real-time data collection functions, with one-key drilling function and anti-stucking functions, suitable for groundpressure prevention;The national III standard explosion-proof diesel engine monorail crane locomotive realizes multi-point direct transportation of hydraulic supports (48T); the drilling and bolting jumbo can drill with one key, and realize the automatic construction of anchor rods and anchor cable holes.

All products have corresponding quality control standards, which are completed simultaneously with design drawings and processes, and are recorded in the information management system.

All products have corresponding quality control standards, which are completed simultaneously with design drawings and processes, and are recorded in the information management system.Each product is marked with a unique permanent laser identification code when it is submitted for inspection. The inspection items and records correspond to each identification code, which realizes:1. Unique product quality identification; 2. Traceability of product quality problems; 3. Lifelong responsibility for product quality; 4. The basis for improvement is accurate and sufficient, and the improvement effect is tracked in place.

In recent years, we have been rated as Hebei Provincial Enterprise Technology Center, Shijiazhuang Coal Mining Machinery Engineering Technology Research Center, Hebei Coal Mine Safety Equipment Engineering Technology Research Center (in preparation), Hebei Coal Mine Safety Equipment Inspection and Testing Platform (in preparation), The public technology research and development platform for coal mining machinery and equipment of the Ministry of Commerce has been fully affirmed by relevant departments in terms of product research and development, quality inspection, engineering technology transformation, and public services.

In recent years, we have been rated as Hebei Provincial Enterprise Technology Center, Shijiazhuang Coal Mining Machinery Engineering Technology Research Center, Hebei Coal Mine Safety Equipment Engineering Technology Research Center (in preparation), Hebei Coal Mine Safety Equipment Inspection and Testing Platform (in preparation), The public technology research and development platform for coal mining machinery and equipment of the Ministry of Commerce has been fully affirmed by relevant departments in terms of product research and development, quality inspection, engineering technology transformation, and public services.In the future, the engineering laboratory will obtain income through technical patents and paid use of new products, undertaking technical engineering research and development tasks for coal mine safety equipment industry, government scientific research funding, technical training and technical services, etc. "The virtuous cycle operation mode, and strive to achieve the sustainable development of the laboratory.