High-Performance Borehole Drilling Machine/200m Deep Diesel Geotechnical/Water Well Hydraulic Core Drilling Rig

Speedmade Industries Co., Ltd.- After-sales Service:Video Technical Support

- Warranty:1 Year

- Certification:ISO 9001:2000

- Condition:New

- Motor:AC Motor

- Drill Hole Diameter:200-250mm

Base Info

- Drill Hole Depth:>200m

- Bit Type:Diamond Bit, Cone Bit

- Drilling Way:Rotary

- Type:Core Drilling Rig

- Condetion:New

- Application:Coal, Ore, Water Well, Geotechnical Investigation

- Video Outgoing-Inspection:Provided

- Place of Origin:China

- Chuck:Hydraulic Chuck

- Power:Electric

- Weight:2000 Kg

- Key Selling Points:Competitive Price

- Drilling Diameter:300mm, 100mm, 200mm

- Head Angle Range:360 Degree

- Spindle Hole Diameter:63mm or 95mm

- Dimensions:60X800X1400mm

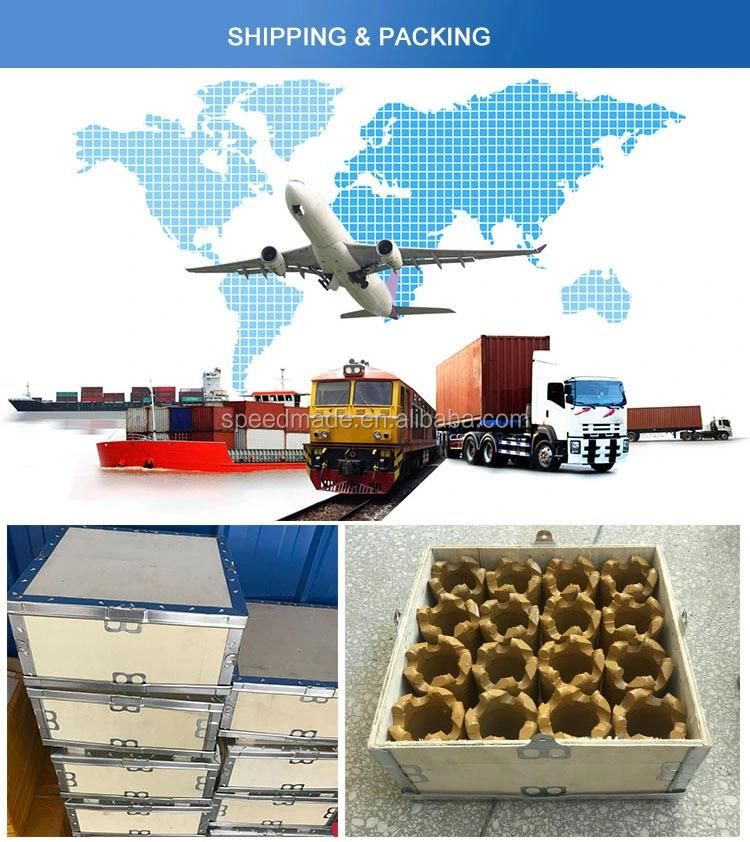

- Transport Package:Exported Package

- Specification:200

- Trademark:speedmade

- Origin:China

- HS Code:82071990

- Production Capacity:2000piece,Pieces Per Month

Description

Basic Info.

Drill Hole Depth >200m Bit Type Diamond Bit, Cone Bit Drilling Way Rotary Type Core Drilling Rig Condetion New Application Coal, Ore, Water Well, Geotechnical Investigation Video Outgoing-Inspection Provided Place of Origin China Chuck Hydraulic Chuck Power Electric Weight 2000 Kg Key Selling Points Competitive Price Drilling Diameter 300mm, 100mm, 200mm Head Angle Range 360 Degree Spindle Hole Diameter 63mm or 95mm Dimensions 60X800X1400mm Transport Package Exported Package Specification 200 Trademark speedmade Origin China HS Code 82071990 Production Capacity 2000piece/Pieces Per MonthProduct Description

Product DescriptionHigh-Performance Borehole Drilling Machine/200m Deep Diesel Geotechnical/Water Well Hydraulic Core Drilling Rig

SP-200 Drilling rig is light shallow hole drill with hydraulic feed.Applicable to the exploration, geophysical exploration, road and building exploration and small water well drilling, etc.

Application:

1. With hydraulic automatic feeding device, elevated drilling efficiency.

2. The holding mechanism with upper spherical jaws is used as substitute for chuck. The rod can be replaced without shutdown.

3. Centralized handles, easy operation, safe and reliable.

4. The pump and diesel engine are installed on common base frame in order to have a compact structure and occupy small field area. lightweight, high detachability, easy transportation and suitable for the operations in plains or mountain areas.

SP-200 High-Performance Core Drilling Rig:

Product Features:

1. Good stability and high reliability.

2. Multilevel positive and reverse rotate speed.

3. The complete hydraulic chuck and vertical spindle, hydraulic chuck on top and manual chuck at the bottom

4. Steel Skid mounted with Hydraulic retraction system

5. Convenient to transport with the small volume and light weight.

6. Perfect frame's rigidity, low center of gravity and good stability.

Product Parameters

The technical parameters of the SP-200 drilling rig:

| Type | SP-200 Drilling Rig |

| Drilling depth(m) | 200 |

| Drilling rod caliber | 60mm |

| Drilling angle | 90°~75° |

| Cylinder stroke(mm) | 360 |

| Spindle speed(r/min) | Positive rotation rate: 64128287557550 Reverse rotation rate: 3585135195330480 |

| Spindle hole diameter(mm) | Φ63 or Φ95 |

| Spindle output torque(N.M) | 1700 |

| Spindle stroke(mm) | 500 |

| Spindle driving force max.(KN) | 37 |

| Spindle lifting power max.(KN) | 50 |

| Lifting speed (r/m) | 64/128/287/557 |

| Single rope lifting power(KN) | 20 |

| Steel wire rope diameter(mm) | Φ11 |

| Mode of chuck | hydraulic chuck or ball-type chuck |

| Weight(power unit excepted)(kg) | 750 |

| Dimensions(LxWxH)(mm) | 1860x800x1400 |

| Diesel engine | ZS1110(14.7KW) |

| Electric motor | Y160L-4(15K |

The standard spindle hole diameter of SP-200 drilling rig is 63mm, and it can be equipped with large spindle hole diameter 95mm per customer's requests, which can lock the wireline NQ and HQ rods directly to improve efficiency of wireline drilling. This rig is equipped hydraulic chuck on top and the manual chuck at the bottom, which makes the rig more stable during drilling, increase the drilling efficiency and reduce the drilling accidents happened.

WHY CHOOSE SPEEDMADE INDUSTRIES Co.,Ltd?

1.Our propose is to supply the most suitable borehole drilling machine to users.

You can get a full range of product selection advice and product customization without paying any fees.

2.We have two special groups of design teams. One team of after-sales engineers with more than 30 years of construction experience at home and abroad, other team of designers who graduated from well-known universities and have rich work experience. We will combine a wealth of practical construction experience and the most advanced professional theoretical knowledge to meet your various demands.

3.We are not only familiar with borehole drilling rig, but also familiar with the human environment, construction environment and strata in the construction field at home and abroad. Provide you with the greatest technical support, save costs and create the greatest value with you. Yes, choosing us is your best decision.

4. Support overseas train and maintain. We do ten days overseas train for free,after you buy our machine.

5. One year Warranty. Speedmade knows the various needs of the water well service companies and operators worldwide.

Customers who buy rigs from us can benefit from great saving thus boost their bottom line.

FACTORY SHOW

-PAYMENT-

DIY customization: please provide your rock formation information or detailed size drawings.

Free samples: some samples can be provided free of charge.

Trading:EXW, FOB, CFR, CIF, DDU such as.

Payment:T/T L/C,D/A,D/P,Western Union,MoneyGram.

Delivery time: normally 7-12 days